Modern cosmetics manufacturing is a perfect fusion of technology and aesthetics, with each product embodying complex R&D processes and precise production techniques. From the initial conceptual spark to the final product reaching the consumer, a Cosmetics Manufacturer oversees hundreds of steps and rigorous quality control. This industry pursues not only aesthetic effects but also prioritizes safety, stability, and innovation. Top global Cosmetics Manufacturer companies invest billions of dollars annually in research and development. Understanding the complete cosmetics manufacturing process not only helps consumers make more informed choices but also reveals the core competitiveness of this multi-billion dollar industry.

Phase One: Formula Development and Laboratory Testing

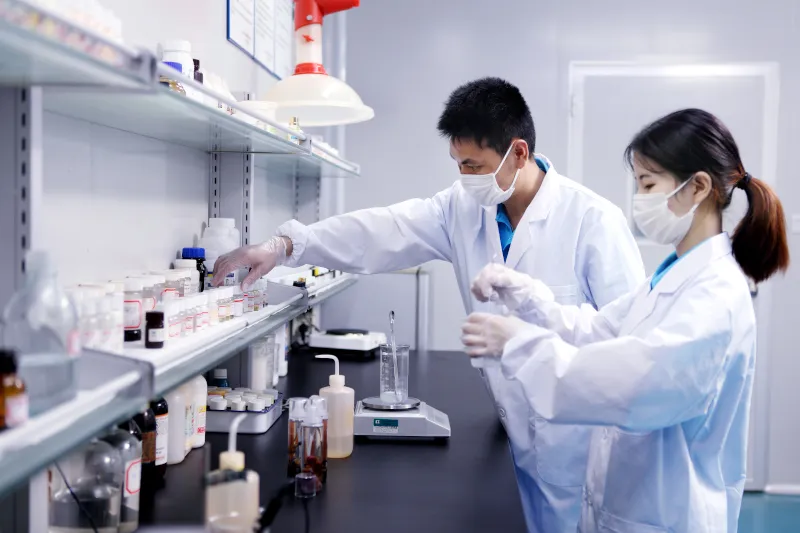

The Scientific Foundation of Formula Design

Cosmetics formula development begins with a deep understanding of skin physiology and chemical principles. The R&D team within a Cosmetics Manufacturer, typically composed of chemists, biologists, and dermatology experts, first defines the product’s primary functional goal—whether it’s moisturizing, anti-aging, sun protection, or specialized care. The basic formula architecture consists of three key elements: active ingredients (like Vitamin C, Hyaluronic Acid), the base carrier (aqueous phase, oil phase, or emulsified system), and functional additives (preservatives, fragrances, colorants).

Modern formula development has entered the era of “precision skincare.” Scientists consider factors like molecular size of ingredients, percutaneous absorption rates, compatibility between components, and the final product’s sensory properties. For instance, when developing an anti-aging cream, the team must balance retinol’s efficacy with its potential for irritation, while ensuring the synergistic antioxidant effects of Vitamins E and C are not compromised. This process often requires months or even years of iterative trials, utilizing advanced computer modeling and in vitro test models to predict formula performance.

Lab-Scale Trials and Stability Assessment

After a preliminary formula is established, the lab produces small-batch samples (typically 100 grams to 1 kilogram) for comprehensive testing. Accelerated Stability Testing is a critical phase. Samples are stored under extreme temperature conditions (e.g., 4°C, 25°C, 40°C) for weeks or months to observe changes in their physicochemical properties. Test items include:

-

Thermal Cycling Tests: Simulating temperature fluctuations during transport and storage.

-

Centrifugation Tests: Evaluating the stability of the emulsion system to prevent phase separation.

-

Light Exposure Tests: Checking the photosensitivity of colorants and active ingredients.

-

Microbial Challenge Tests: Verifying the effectiveness of the preservation system.

Concurrently, R&D personnel assess the product’s user experience—texture, spreadability, absorption rate, fragrance, and packaging compatibility. This stage may yield dozens of revised versions until all parameters meet the ideal standards. Many premium brands also conduct preliminary consumer blind tests at this stage to gather feedback on the product’s sensory attributes from the target demographic.

Phase Two: Industrial Production and Quality Control

Scale-Up and Process Translation

Successfully translating a lab formula to industrial-scale production is a major challenge for any Cosmetics Manufacturer. Production engineers must adjust numerous parameters: mixing speed, heating/cooling rates, addition sequences, homogenization pressure, etc., to ensure batch-to-batch consistency during large-scale manufacturing. Cosmetics production primarily employs the following processes:

The Emulsification Process is core to most cream-based products, involving the homogeneous mixing of oil and water phases using high-shear equipment. Modern factories use computer-controlled emulsification kettles capable of precisely regulating temperature curves and mixing energy to ensure the formation of stable microparticles (typically 1-10 microns in diameter).

For water-based products like serums, the Dissolution and Filtration Process is more critical. Active ingredients must be dissolved at specific pH and temperature levels, followed by multi-stage filtration (from 5 microns down to 0.22 microns) to remove impurities and microorganisms.

The Filling and Packaging stage also requires precise control. Automated production lines can complete filling, sealing, labeling, and boxing at speeds of tens to hundreds of units per minute, while vision inspection systems automatically reject defective products.

The Complete Quality Control System

The cosmetics industry adheres to quality standards on par with food and pharmaceutical sectors. Raw Material Incoming Inspection is the first checkpoint. Each batch of raw materials requires a Certificate of Analysis from the supplier and undergoes internal verification testing. In-Process Quality Control during production involves real-time monitoring at critical control points: parameters like temperature, pH, viscosity, and specific gravity are continuously recorded.

Finished Product Release Testing covers both physicochemical and microbiological aspects:

-

Physicochemical Tests: Color, odor, texture, active ingredient content, heavy metal content.

-

Microbiological Tests: Total viable aerobic count, molds and yeasts, pathogenic microorganisms (e.g., Staphylococcus aureus, Pseudomonas aeruginosa).

-

Packaging Integrity: Seal integrity, compatibility, functional testing.

Internationally renowned brands and their contract Cosmetics Manufacturer partners typically enforce internal control standards that are ten times stricter than legal requirements. For example, while Chinese regulations may allow a total bacterial count of ≤500 CFU/g for eye-area cosmetics, many companies’ internal standards set the limit at ≤50 CFU/g.

Phase Three: Innovation Trends and Future Outlook

Green Manufacturing and Sustainable Development

The global cosmetics industry is rapidly transitioning towards Green Chemistry and Sustainable Manufacturing. This is reflected on multiple levels: using biodegradable ingredients, developing waterless formulas to reduce water consumption, utilizing production facilities powered by renewable energy, and designing recyclable or refillable packaging. A forward-thinking Cosmetics Manufacturer invests in these areas to meet evolving consumer and regulatory demands.

Technologies like plant stem cell extraction, bio-fermented ingredients, and upcycled raw materials (e.g., extracting actives from fruit processing waste) are transforming the supply chain. Carbon Footprint Tracking and Water Stewardship during production have become standard practice for industry leaders, with some factories achieving zero waste to landfill and carbon-neutral production.

The Convergence of Personalization and Smart Manufacturing

Personalized Cosmetics, based on DNA testing, skin microbiome analysis, and AI algorithms, are on the rise. Some advanced Cosmetics Manufacturer factories have deployed flexible production lines capable of manufacturing small-batch, custom-formula products (as low as 50 ml) based on individual customer skin test data.

The application of Smart Manufacturing 4.0 in cosmetics plants includes: IoT devices for real-time production parameter monitoring, AI for predictive equipment maintenance, and blockchain technology for tracing raw material origins and the entire production journey. These technologies not only enhance efficiency but also increase product transparency and consumer trust.

Conclusion: The Perfect Loop from Science to Art

Cosmetics manufacturing is the process of transforming rigorous science into sensory art. Behind each product lies comprehensive consideration from molecular structure to consumer experience, representing the culmination of countless tests and adjustments by a skilled Cosmetics Manufacturer. Understanding this process allows consumers to choose products more rationally and industry professionals to grasp the core of quality more deeply. In the future, with technological advancement and increased consumer awareness, the role of the Cosmetics Manufacturer will continue to evolve, finding a better balance between innovation, safety, and sustainability, delivering more effective, safer, and more enjoyable beauty experiences to global consumers.

Whether you are a newcomer to the cosmetics industry, a professional in a related field, or a consumer curious about the stories behind products, understanding the complete journey “from formula to finished product” and the pivotal role of the Cosmetics Manufacturer will empower you to make wiser judgments and choices in this field where value and aesthetics are equally paramount.